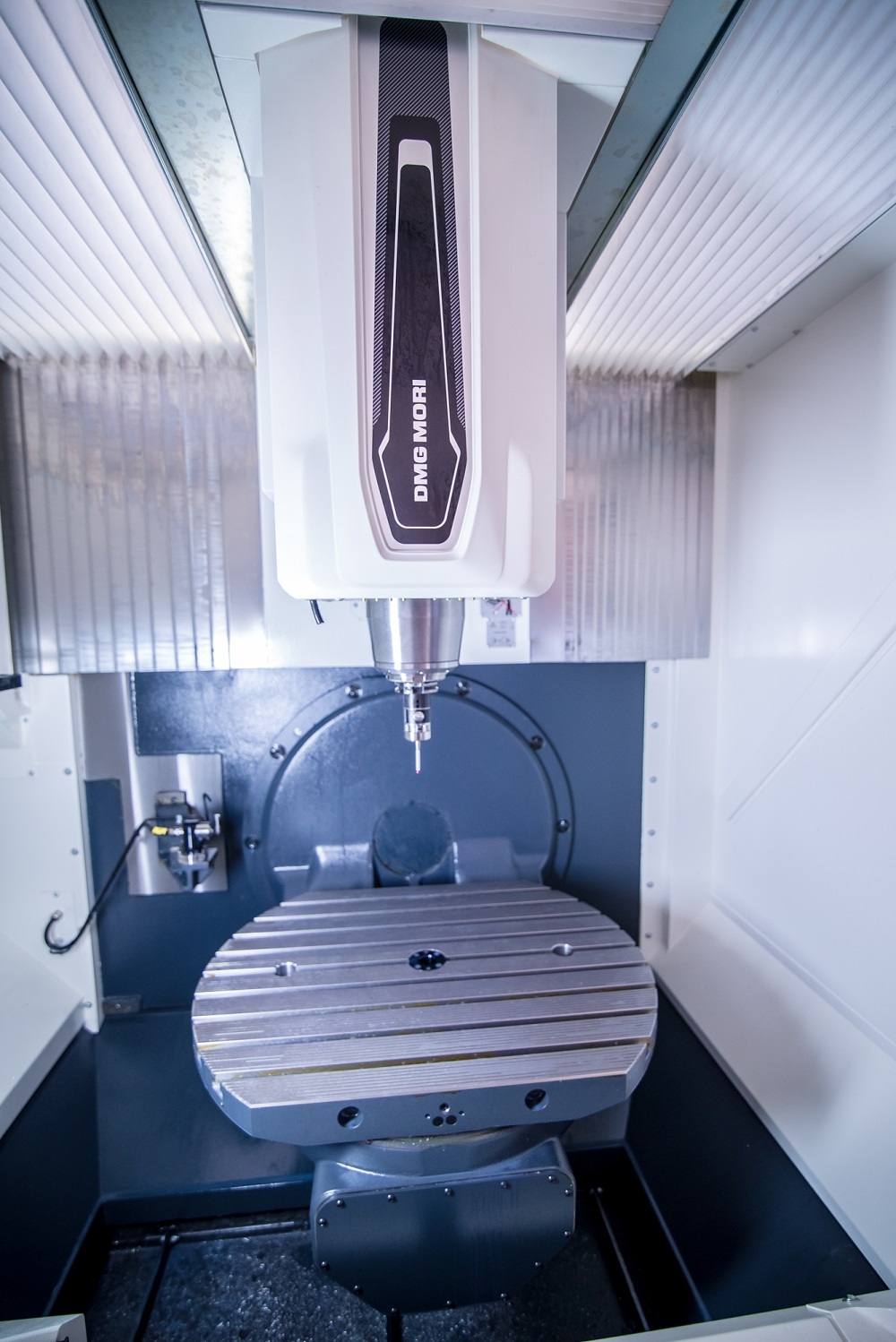

5-AXIS MILLING

CNC Bearbeitung

CNC machining with the use of 5-axis milling machine allows for an almost limitless possibilities of shapes and sizes that can be successfully processed.

With the use of DGM MORI CMX 70 U milling machine we can work on objects up to 350 kg in one vise!

ADVANTAGES OF 5-AXIS MILLING

Increased productivity achieved due to processing of complex shapes in one setting.

Precision of production due to not moving the milled object from one machine to the other

High efficiency of the process: faster milling speed as well as reduction of tool vibrations due to ability to use shorter tools.

Better production efficiency at shortened implementation times.

Improved quality of milled surface.

Time and money efficiency, due to smaller number of devices used in the process.

WHY DGM MORI CMX 70U MILLING MACHINE?

It is a guarantee of the highest rigidity, due to innovative C-frame construction made of grey iron as well as patent protected swivel/tilt NC control.

The highest efficiency of milling is achieved due to implementation of hard milling spindle, with 12.000 rpm.

Reduced operating time due to implementation of 30-position tool holder with double gripper.

Increased productivity and effectiveness due to dynamic drive – up to 20% shorter auxiliary times and fast feed: 30 m/min on all linear axes.

Modern, patent protected swivel/tilt NC steering table, with maximum mounting surface of ø 800 × 620 mm

Reliable 3D steering system due to SIEMENS-operated DMG MORI SLIMline® Multi-Touch 19” control panel.

Contact us!

We will be happy to advise you on the best solutions.

KISIELEWSKI Sp. z o. o.

MAIN ADDRESS, PRODUCTION OFFICE:

Ligota Wołczyńska 70

46-250 Wołczyn

POLAND

+48 77 543 23 29

OFFICE

ul. Wagonowa 2d/3

53-609 Wrocław

NIP / VAT UE number: PL 751 177 18 02

REGON: 161444999

KRS: 0000407629

Sąd Rejonowy w Opolu, VIII Wydział Gospodarczy

Kapitał zakładowy / Share capital:

500 000 PLN

SOCIAL MEDIA