Kisielewski company uses the newest technology of cutting type: edge-precision with application in motors with high efficiency, as well as in generators and electrical machines.

Thanks to very specific and individual laser parameters, we can perform the cutting line with very high precision and accuracy.

All cut components are without burr and stacking process does not require additional processing such as deburring with additional varnishing of the lamination.

We are supplied by the world-known steel mills for magnetic and carbon steel as well as we proceed the raw material delivered by customer.

All special raw material requirements are checked with the mill and after its delivery can be processed in our workshop. For the magnetic steel, the loss can be checked by Epstein test.

Technical parameters:

-

- Working table 1500 x 3000 mm;

- Power 2 kW;

- Processed raw materials:

-

- Carbon steel up to 20mm thick;

- Stainless steel up to 15mm thick;

- Aluminum up to 15mm thick;

- Copper up to 6mm;

- Brass up to 8mm thick.

Technical parameters:

Working table 1500 x 3000 mm;

Power 4 kW;

Processed raw materials:

-

- Carbon steel up to 20mm thick;

- Stainless steel up to 15mm thick;

- Aluminum up to 15mm thick;

- Copper up to 6mm;

- Brass up to 8mm thick.

The long reach robot ideally suited for different applications, mostly for material handling that can automate some of the most tedious, dull, and unsafe tasks in a production line, is one of the easiest ways to add automation, enhances the efficiency of our production line, and increases customer satisfaction by providing quality products in a timely manner. The increased working range of the arm helps to cover many production stages including laser table, storage area, sheets pickup. It also helps to divide the cut components in reference to the shape, weight or other parameters.

Working parameters:

-

- reach – 3100 mm;

- number of axis – 6 (which allows to do very precise and fast movements after the setup)

- load capacity – 210kg

During working performance of the milling machine, the tool is moving in line axis: X, Y,Z and rotate in axis A and B. It machines the component completely in required direction with the easy access to it.

Working parameters:

-

- Axis X- 750 mm

- Axis Y – 600 mm

- Axis Z – 520 mm

- Working table max. Load: 350kg

- Table diameter:800 mm

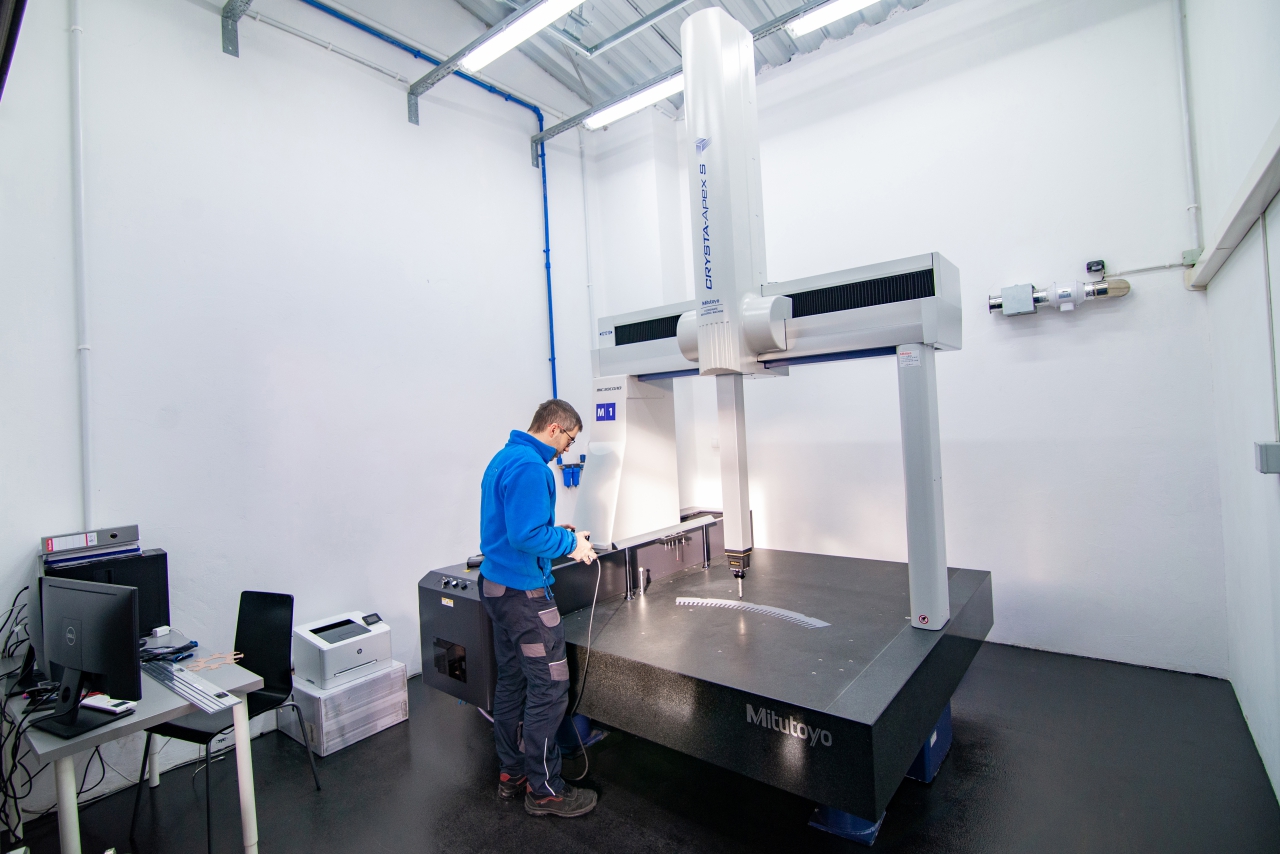

All necessary geometrical measurements as well as scanning, surface roughness measurement and reverse engineering are performed on the measuring machine with the following working parameters:

-

- Working table area: 1200mmx1200mmx900mm;

- Temperature compensation: (16°C do 26°C) allows required accuracy not only in air-conditioned chamber but also in the workshop;

- Max. weight of the component to be measured: 2000kg;

- Max. height of the component to be measured: 1000mm;

- Accuracy of the measurements: E0, MPEE0 = +/-(2,3 + 4L/1000) µm, L – mm.

Each process, performed in Kisielewski company, needs to be checked, confirmed using very accurate measurements which are carried out during the production and reported acc. to the customer requirements. All of these activities are performed directly in the workshop, which shorten the production time and provide keeping the required parameters. Quality dep. Is also equipped with the standard measuring devices: calipers, micrometers, gauge blocks, bore gauges) as well as in other more advanced tooling and devices.

The line allows to cut the material from the coils into sheets in the fully automatic process.

Working parameters:

-

- thickness range of raw material from 0,3 up to 1mm,

- width range of ready sheets from 400 up to 1500 mm,

- length range of ready sheets from 500up to 3050 mm,

- max. coil diameter – up to 5000kg.

This hydraulic press is used for bending components with very high precision both in manual and semi-automatic cycle. The setups of the hydraulic cylinders, bending and torsional bars allows high precision and repeatability of bending.

Working parameters:

-

- max. press pressure – 40t

- max. bending length – 2000mm.

This machine allows manufacturing ventilation segments automatically which make the component made more precisely, with repetitive and controlled quality of welds. It is possible to adjust 26 different parameters during the process working with loading and positioning parts.

Working parameters:

-

- line pressure system,

- power 100kVa,

- max. welding current 60 kA,

- max. pressure force 1242 daN –> 12420 N,

- cooling with water,

Hydraulic press for pressing stacked poles

The press is used for stacking and pressing pole stacks up to 1200mm height, for single pole sheet dimensions: 700mmx550mm. The max. pressure force up to 100t. It was improved to receive 0,4mm accuracy after the process. The pressure force is focused in the center of gravity of the component, which allows receiving very accurate dimensions, which are required for such type of component. The reports confirms the quality of manufacturing. The press is under regular improvement and all customer requirements are fulfilled.

Epstein Frame device

It is used for testing the losses for the raw materials: electrical steel and other soft magnetic materials used in our company for manufacturing components for motors and generators.

Contact us!

We will be happy to advise you on the best solutions.

KISIELEWSKI Sp. z o. o.

MAIN ADDRESS, PRODUCTION OFFICE:

Ligota Wołczyńska 70

46-250 Wołczyn

POLAND

+48 77 543 23 29

OFFICE

ul. Wagonowa 2d/3

53-609 Wrocław

NIP / VAT UE number: PL 751 177 18 02

REGON: 161444999

KRS: 0000407629

Sąd Rejonowy w Opolu, VIII Wydział Gospodarczy

Kapitał zakładowy / Share capital:

500 000 PLN

SOCIAL MEDIA